Timber Seasoning

Timber is seasoned to dry out the timber to bring it to a usable and workable condition. More than half the weight of freshly cut timber consists of moisture or sap. Before the timber can be used a large part of the moisture must be removed.

Reasons for Seasoning

- To prevent shrinkage, splitting, checking and warping.

- To achieve greater stiffness and strength.

- To allow penetration of preservatives

- To obtain a surface that will accept paint, polish or glue.

- To protect against decay.

Moisture Content of Timber

Water is stored in wood in two main forms:

- As free water in the vessels and/or cells, used to move nutrients within the tree.

- As cell (or bound) water, which is an integral part of the cell walls.

Initial seasoning first removes the free water contained from within the cells to a moisture content of 25 to 35 percent.

The cell walls still contain moisture. This state is known as the fibre saturation point. With further seasoning the combined moisture within the walls of the cells begins to dry out and the cells and timber begin to shrink, so this part of the process must be carried

out with careful control over drying rate.

The timber continues to dry out until it is brought to the moisture content required, usually about 12-15%.

Methods of Seasoning

Methods of Seasoning

Air Seasoning

The timber is stacked on foundations to keep it off the ground. Strips of wood (about 38 x 19 mm) are placed between the layers of boards to allow air to circulate. Ends of boards may be painted to retard drying and prevent splitting.

A waterproof covering is placed over the stack to protect the timber from the sun and the weather.

Air seasoning is slow, taking up to a year for a piece 25 mm thick and considerably longer for thicker pieces. But the timber produced is well suited to outdoor work.

Kiln Seasoning

Kiln seasoning is done in a large oven-like structure in which air circulation, humidity and temperatures are controlled. The timber is stacked on the trucks in the same way as for air drying. The trucks are on rails so that they can be moved into the kiln.

Care must be taken to see that the drying process while removing the free water is not too rapid, as at this stage the timber is susceptible to degrade (damage) by checking and collapse.

Many types of softwood, such as Radiata Pine, can be kiln dried easily and fairly cheaply from the green condition. But many of the Australian hardwoods are so slow in drying that their kiln drying is uneconomical. It is, however, satisfactory and economic to season them by the combined process of air and kiln drying mentioned below.

Types of Seasoning Kilns

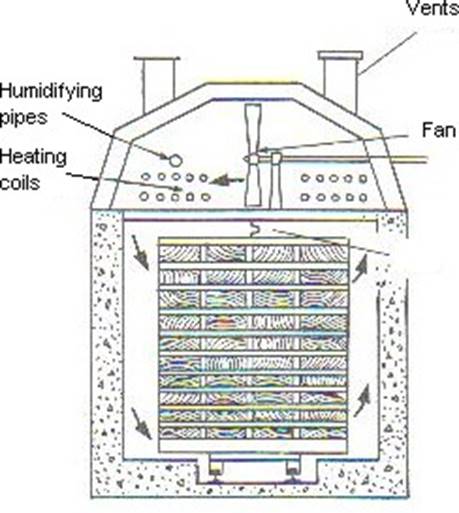

Compartment Kilns

Circulation is induced by fans forcing air over heating coils and humidifying sprays and through the timber stack.

The fans are reversible to allow uniform seasoning on each side of the stack. Kiln conditions are uniform and can be regulated to suit the stage of seasoning.

The fans are reversible to allow uniform seasoning on each side of the stack. Kiln conditions are uniform and can be regulated to suit the stage of seasoning.

Compartment kiln

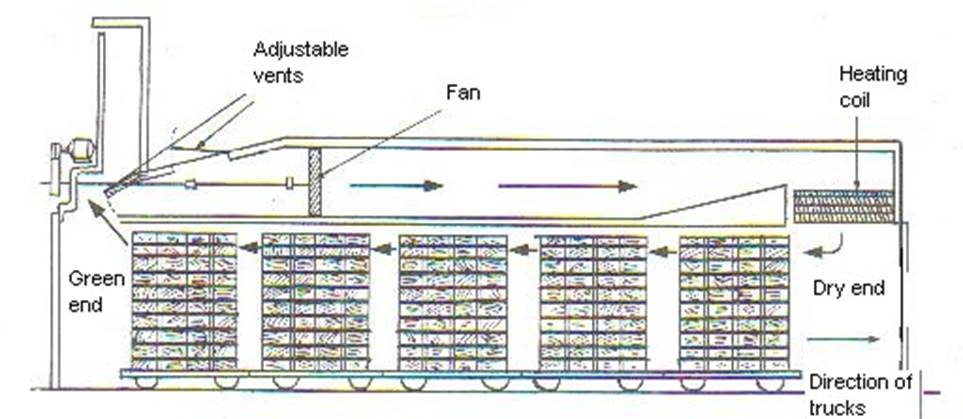

Progressive Kilns

In this type of kiln the conditions at one end of the kiln differ from those at the other end.

An unbroken line of trucks, all at different stages of drying, extends through the kiln. As a truck of green timber enters at the cool, moist end, another is removed from the hot, dry end ready for use; the drying process is continuous.

Heated air is circulated by fans along the kiln from the hotter and drier end to the cooler and moister end. As it passes through the timber it gradually cools and picks up moisture, thus, the drying conditions at the greener end are less than those at the dry end.

Progressive kiln

Example of a Hildebrand progressive timber dry kiln (counterflow principle) which was installed in 1978 at BSW Timbers in Great Britain – still in operation today.

Combined Seasoning

- The timber is first air dried for several months, the actual time depending on the species of timber, thickness and climate. The slow air drying, until the free moisture has been removed (i.e., to fibre saturation point – 25-30% M.C.) reduces the tendency to degrade by warping, checking and collapsing.

- The timber is then kiln dried to remove the combined moisture from the cell walls to the required moisture content. This can be done rapidly in several days to a week or so.

Advantages of Kiln Drying

- Kiln drying permits drying to the exact M.C. required, which may be much less than that of air dried timber.

- The carefully controlled conditions can minimise degrade – seasoning defects which occur while drying.

- The heating of the timber while in the kiln kills eggs, larvae and adult borers which may be present in the wood.

- Although capital costs may be higher, greater turnover is possible by reductions in drying time, and less timber yard storage space required.